DESCRIPTION: Patented dual arm action pushes the sash open while pulling the hinge side of the sash to the open position. When properly installed this operator results in almost effortless operation of both casement and awning-type windows of many sizes and weights, even those with insulated and double-insulated glass (typical operating torque is less than one foot-pound to open and close a 60 lb. sash 90º).

INVENTORY/COST REDUCTIONS The same operator, when mounted on the side jamb, and combined with the recommended awning hinge, can be used on an awning window also. The result is reduced volume of both hardware and window parts and fewer sizes and models to inventory which turns inventory faster and reduces cost. The snap-on cover has a flange which works as an escutcheon. The cover eliminates visible light around the operator and also saves time and money by hiding any cover routing imperfections. Note, also, that the mounting location and the full 90° opening capability provides unrestricted egress access.

PRODUCT APPLICATION ASSISTANCE: If you are designing a new window profile, or are having difficulty selecting hardware for your window, please contact Truth. Our highly trained Product Specialists can assist you with the selection of the appropriate hardware to meet your performance requirements, as well as providing personalized application drawings.

LOGO OPTIONS: Have you ever considered personalizing your window? The operator handle has the ability to attractively display your company name or logo. For further details on where your company identification would appear, please refer to the following drawings.

WARRANTY: Protected under the terms of the Truth Warranty for Window and Door Manufacturers and Authorized Distributors. Refer to Truth’s Terms and Conditions for further details.

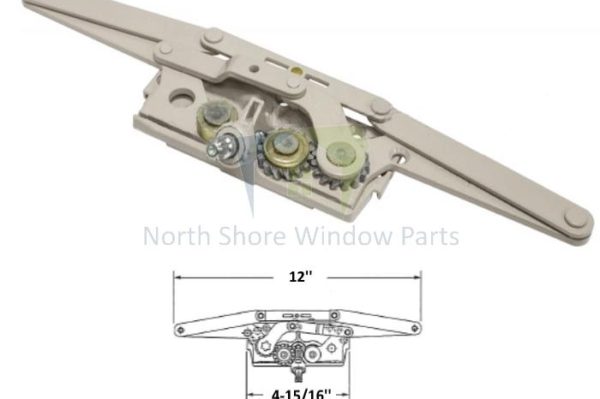

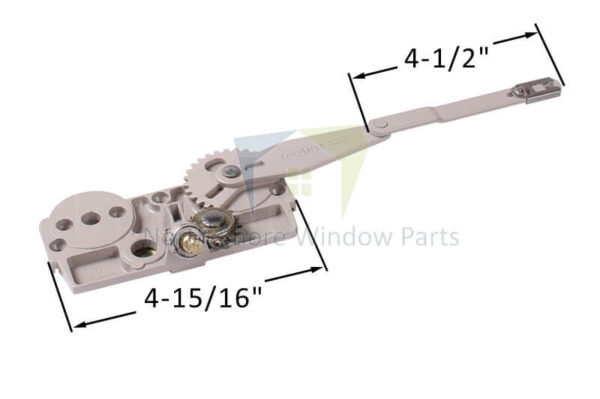

MATERIAL: High-pressure die-cast zinc operator base. Hardened steel drive worm and gears. High-strength plastic operator cover.

CORROSION PROTECTION: Truth’s E-Gard® Hardware has a multi-stage coating process that produces a superior physical and aesthetic finish. Plus, it is resistant to a wider range of corrosive materials, including industrial cleaning materials and environmental pollutants. This proprietary process has been tested to be approximately three times better than common zinc plated finishes.

For the severe conditions associated with coastal areas, Truth has developed certain product lines utilizing either CoastGard® Hardware, or stainless steel hardware. See Tech Note #7 for further information about corrosion protection and these special hardware options.

FINISH: Electrostatically applied, durable coatings that provide excellent resistance to chipping, scratching and corrosion while maintaining color stability for years in direct sunlight. Please refer to Truth’s Color Chart for examples of Truth’s most popular finish options. Truth also offers a wide range of decorative “plated” finishes – contact Truth for additional information on availability of these finishes on specific product lines.

ORDERING INFORMATION:

- Choose operator style desired (specify by part number).

- Specify finish number.

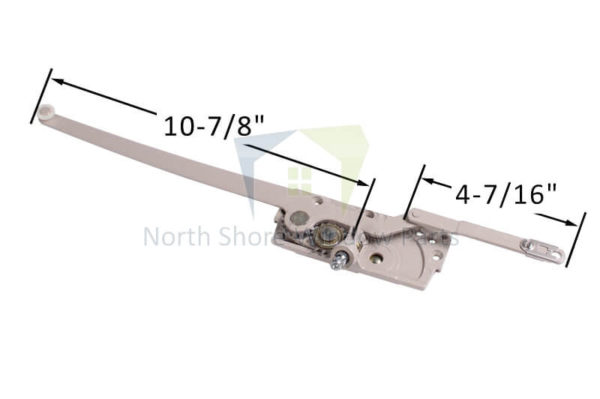

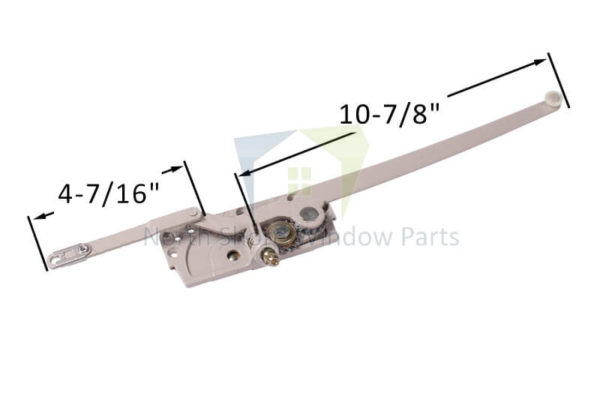

- Specify right-or left-hand (determined by the side the hinge is on when viewed from the outside).

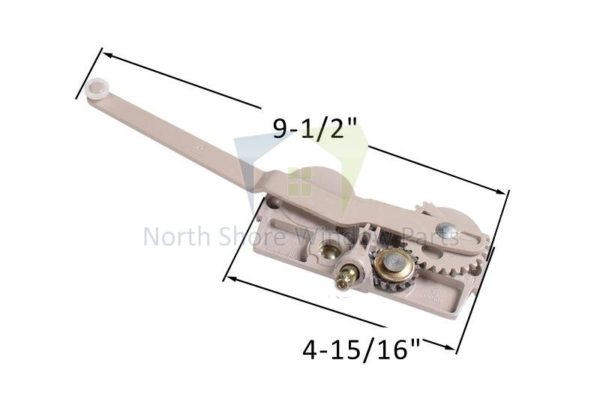

- Select mounting hardware (sold separately): #11454 – Contour Handle (painted) or #10579 – Roto Gear Operator Handle shown above (painted). Optional handle and cover style, such as Truth’s Folding Handle, are also available. #10341 – Operator cover (specify finish number). Face-mounted Track and handed Stud Brackets – select from tables in the following drawings. Optional brackets for special profile applications – see Brackets & Track Section. #21306 – Protective red plastic spline cap (optional).

RECOMMENDED SCREWS:Types of screws required determined by material of profile used. Refer to drawings for complete information on screw type and quantity needed (sold separately). For additional information regarding screw selection, see Truth Tips and Tech Note #11.

TRUTH TIPS:

- Operator handing is determined by the hinge side when viewed from the outside.

- If operator placement, as calculated in Figure #1, is not desirable, the operator can be shifted up to .343″ (8.7 mm) away from the hinge side of the window. Shifting the operator will cause slightly higher operator torque and reduces resistance to wind load. If 90° of opening is not necessary, the operator can be shifted toward the hinge side of the window. The best operator performance can be achieved by minimizing dimensions “A” and “X” – see Figure 1.

- When a Dual Arm Operator is installed in high rise applications over two stories, a Truth Limit Device, to restrict the amount of opening, is recommended. Contact Truth for wind load information.

- Sash weight should be limited to 60 lbs. to insure ease of operation for the lifetime of the window. When used on a sash weighing over 60 lbs., operating torque will noticeably increase and operator life will be reduced.

- Truth recommends that a Snubber be used at the center of the hinge side on any casement window which has a tendency to bow outward at the center in the closed position. Adding a Snubber may increase the negative air pressure rating of a casement window.

- A Spline Cap (part #21306) is available to protect the operator splines from dirt and other windows from damage during shipping, installation and final building construction.

- The Dual Arm Operator should not be used in conjunction with Butt Hinge or 4-Bar Hinges (except the #34.81). In most cases, the motion of the two operating arms do not complement the motion of these types of hinges resulting in higher operating torque.

- The location of the operator and stud bracket (dimension A and B) is based on a sill cover width of 1.938″ (23.8 mm) as specified in Figure. 1. If the sill cover depth must be increased, dimensions A & B will be decreased proportionately and operator torque may increase.

- For accurate hardware placement in vinyl or metal applications, pre-drilling of the window profile is recommended.

- For vinyl window applications, mounting screws should pass through two PVC walls, or one PVC wall and one insert wall. For this reason, it may be necessary to use a longer screw than is recommended.

- For metal window profiles, Truth recommends machine screws. However, in most applications, sheet metal screws will provide adequate holding power.

- When selecting mounting screws for Truth hardware, coating compatibility Is one of the most important criteria. For best corrosion resistance the coating on the screws should be the same as the coating on the hardware. For more information see Tech Note #11.

INCLUDE TRUTH SPECS ON YOUR NEXT PROJECT Window operators shall be provided which allow easy adjustment of window position. The mechanism should be crank operated and provide superior operation throughout the windows range of motion. Connection to the movable sash must be easily detachable for window cleaning and maintenance. Removable EntryGard® interior cover will allow matching hardware styling as well as easier finishing of frame and sill.

Window operators will be of combined push arm and drag arm/link design driven by a hand crank. The operator must be constructed of E-Gard® components, hardened steel worm and gearing and high pressure zinc alloy die castings. High-strength plastic trim cover.

Window operators shall be 15 series EntryGard® Dual Arm Operator as manufactured by Truth Hardware, Owatonna, MN.