WARRANTY: Protected under the terms of the “Truth Warranty for Window & Door Manufacturers & Authorized Distributors”. Refer to Truth’s Terms & Conditions for further details.

MATERIAL: High-pressure die-cast zinc operator housing, crank handle and knob. Hardened steel drive worm and gear. 300 series stainless steel packages are available for most models.

CORROSION RESISTANCE: Truth’s E-Gard® Hardware has a multi- stage coating process that produces a superior physical and aesthetic finish. Plus, it is resistant to a wider range of corrosive materials, including industrial cleaning materials and environmental pollutants. This proprietary process has been tested to be approximately three times better than common zinc plated finishes. For coastal applications, Truth also has stainless steel packages available (see Tech Note #7).

FINISH: Electrostatically applied, durable coatings provide excellent resistance to chipping, scratching and corrosion while maintaining color stability for years in direct sunlight. Please refer to Truth’s Color Chart for examples of Truth’s most popular finish options. Truth also offers a wide range of decorative “plated” finishes – contact Truth for additional information on availability of these finishes on specific product lines (see Truth Tip #9).

RECOMMENDED SCREWS: All Maxim Operator components have been designed to use the same standardized screw style and size, please refer to the drawings for further details. Coating compatibility between the screws and the operator components is very important in order to optimize the corrosion resistance performance. Refer to drawings for complete information on screw type and quantity needed (sold separately). For additional information regarding screw selection – see Truth Tips and Tech Note #11.

TRUTH TIPS:

- Operator base handing is determined by the window hinge side when viewed from the outside.

- Handing of the optional Maxim Nesting Cover is determined by the direction the handle points when in the nested position.

- For accurate hardware placement, pre-drilling of the screw holes in the window profile is recommended.

- For PVC and composite window applications, mounting screws should pass through two profile walls, or one wall and one insert wall. For this reason, it may be necessary to use a longer screw than is recommended.

- For metal window profiles, Truth recommends machine screws. However, in most applications, sheet metal screws will provide adequate holding power.

- When operator is installed in high- rise applications over two stories, a Truth Limit Device, to restrict the amount of opening, is recommended. Contact Truth for wind load information.

- A Spline Cap (#21306) is available to protect the operator splines from dirt and other windows from damage during shipping, installation, and final building construction.

- Truth recommends that Snubbers be used on the hinge side on any casement window that has a tendency to bow outwardly at the center in the closed position. Adding Snubbers may increase the negative air pressure rating of a casement window.

- Decorative plated finishes are not recommended for coastal or highly corrosive environments.

INCLUDE TRUTH SPECS ON YOUR NEXT PROJECT Window operators shall be provided which allow easy adjustment of window position. The mechanism should be crank operated.

The operator must be constructed of E-Gard® coated components. High- pressure die-cast zinc operator base, crank handle and knob. Hardened steel drive worm and gear.

Window Operators shall be Maxim® Series Operators as manufactured by Truth Hardware, Owatonna, MN.

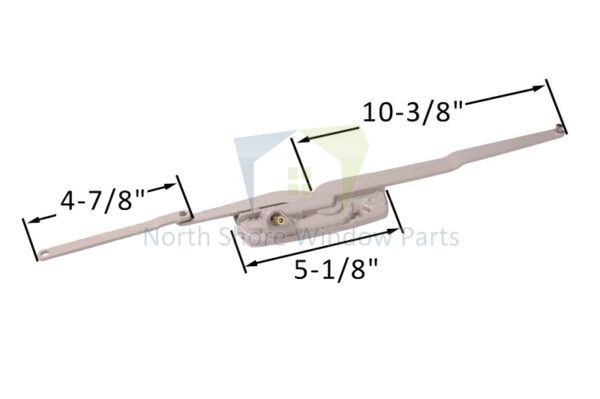

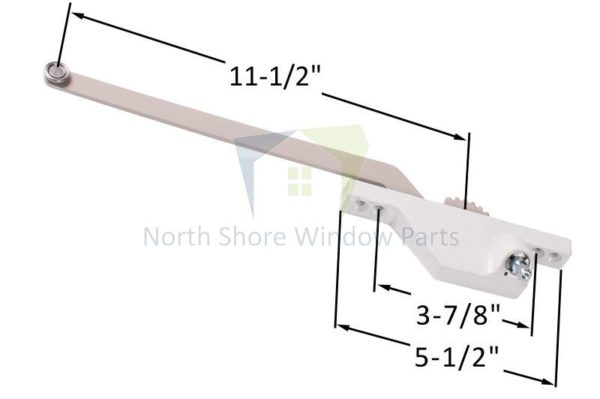

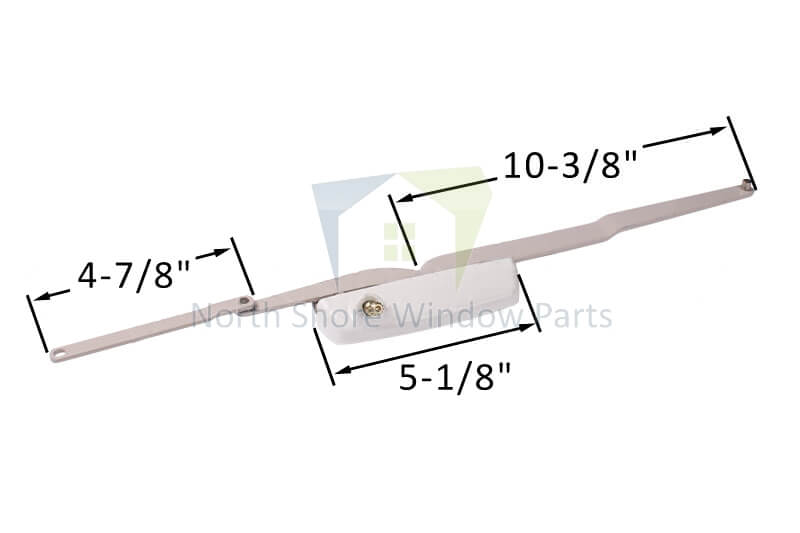

MAXIM® DUAL ARM OPERATOR

Drawings begin on pg. 25d.

- Provides for egress or washability with the same operator in the same location thereby minimizing sill cover inventory.

- Operates sash sizes up to 24″ to 40″ wide, and 84″ high and weighing up to 108 lbs. No need to change operators for standard and custom-sized windows.

- Maxim Dual Arm provides over 7″ of washability with the standard Maxim® 13″ hinge and is compatible with Truth’s standard 10″ hinge, with reduced washability.

- Maxim Dual Arm and Dyad Operators share standardized bracket and mounting location reducing inventory and manufacturing complexities.

ORDERING INFORMATION:

- Specify “standard” or “coastal” package.

- Order item number: #50.00 or #50.01 (low profile) or #50.02 (rear-mount)

- Specify finish number.

- Specify right- or left-hand (determined by the side the hinge is on when viewed from the outside).

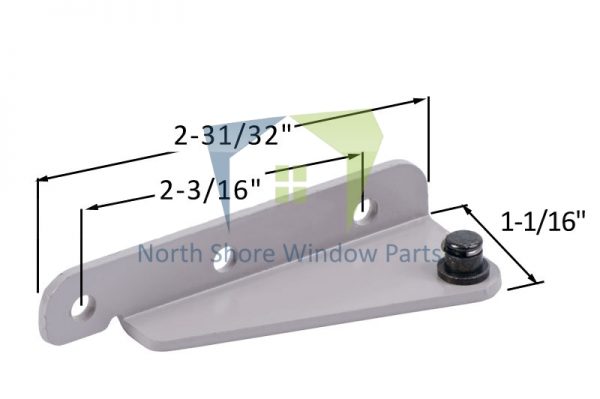

- Select mounting hardware (sold separately). #12510.XX – LH Bracket #12511.XX – RH Bracket, or #11661.XX – LH Bracket (low profile) #11662.XX – RH Bracket (low profile)